قطعات داخلی قابل جابجایی و قابل تعویض شیر که در تماس با محیط جریان قرار می گیرند، در مجموع به عنوان تریم نامیده می شوند. این قسمت ها شامل سیت، دیسک، گلند، اپیسر، گاید، بوشینگ و اسپرینگ است. بدنه شیر، درپوش، پکینگ و قطعات دیگر که در تماس با جریان سیال قرار می گیرند، تریم محسوب نمی شوند.

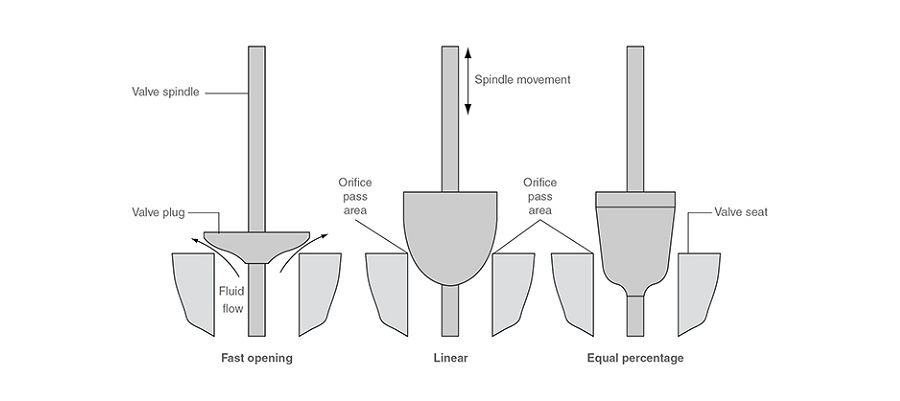

عملکرد تریم شیر توسط رابط دیسک و سیت و ارتباط موقعیت دیسک با سیت تعیین می شود. به دلیل نوع طراحی تریم، حرکات اصلی و کنترل جریان امکان پذیر می باشد. در طراحی های چرخشی، دیسک از نزدیک سیت عبور می کند تا تغییری در باز شدن جریان ایجاد کند. در طرح های حرکت خطی، دیسک به طور عمودی از سیت دور می شود تا یک حفره حلقوی ظاهر شود.

به دلیل ویژگی های مختلفی که برای مقاومت در برابر نیروها و شرایط مختلف مورد نیاز است، می توان از قطعات گوناگونی از تریم شیر استفاده کرد. بوشینگ ها و پکینگ گلندها همان نیروها و شرایطی را که دیسک و سیت تجربه می کنند، ندارند.

نوع سیال، ترکیب شیمیایی، فشار، دما، سرعت جریان سیال و ویسکوزیته برخی از ملاحظات مهم در انتخاب مواد مناسب جهت طراحی و ساخت تریم هستند. مواد استفاده شده می تواند از مواد استفاده شده در ساخت بدنه یا دیافراگم متفاوت باشد.

API با اختصاص یک عدد منحصر به فرد به هر مجموعه ای از مواد استفاده شده در تریم شیر، آن را استاندارد سازی کرده است:

API TRIM NO: 1

Nominal Trim

410

Trim code

F6

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6 (13Cr) (200 HBN)

Seat surface

410 (13Cr)(250 HBN min)

Trim Material Grade

13Cr-0.75Ni-1Mn

Service

For oil and oil vapors and general services with heat treated seats and wedges. General very low erosive or non-corrosive service between -100°C and 320°C. This stainless steel material lends itself readily to hardening by heat treatment and is excellent for contacting parts such as stems, gates, and discs. Steam, gas and general service to 370°C. Oil and Oil vapor 480°C

API TRIM NO: 2

Nominal Trim

304

Trim code

304

Stem and other trim parts

304

Disc/wedge

304 (18Cr-8Ni)

Seat surface

304 (18Cr-8Ni)

Trim Material Grade

19Cr-9.5Ni-2Mn-0.08C

Service

For moderate pressure in corrosive, low erosive service between -265°C and 450°C

API TRIM NO: 3

Nominal Trim

310

Trim code

310

Stem and other trim parts

(25Cr-20Ni)

Disc/wedge

310 (25Cr-20Ni)

Seat surface

310 (25Cr-20Ni)

Trim Material Grade

25Cr-20.5Ni-2Mn

Service

For moderate pressure in corrosive or non corrosive service between -265°C and 450°C

API TRIM NO: 4

Nominal Trim

410 - Hard

Trim code

F6H

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6 (13Cr) (200-275 HBN)

Seat surface

F6 (13Cr) (275 HBN min)

Trim Material Grade

13Cr-0.75Ni-1Mn

Service

Seats 275 BHN min. As trim 1 but for medium pressure and more corrosive service

API TRIM NO: 5

Nominal Trim

410 - Full Hard faced

Trim code

F6HF

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6+St Gr6 (CoCr Alloy) (350 HBN min)

Seat surface

410+St Gr6 (CoCr Alloy) (350 HBN min)

Trim Material Grade

13Cr-0.5Ni-1Mn/Co-Cr-A

Service

High pressure slightly erosive and corrosive service between -265°C and 650°C and higher pressure. Premium trim service to 650°C. Excellent for high pressure water and steam service

API TRIM NO: 5A

Nominal Trim

410 - Full Hard faced

Trim code

F6HF

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6+Hardf. NiCr Alloy (350 HBN min)

Seat surface

F6+Hardf. NiCr Alloy (350 HBN min)

Trim Material Grade

13Cr-0.5Ni-1Mn/Co-Cr-A

Service

As trim 5 where Co is not allowed

API TRIM NO: 6

Nominal Trim

410 and Ni-Cu

Trim code

F6HFS

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

Monel 400® (NiCu Alloy) (250 HBN min)

Seat surface

Monel 400® (NiCu Alloy) (175 HBN min)

Trim Material Grade

13Cr-0.5Ni-1Mn/Ni-Cu

Service

As trim 1 and more corrosive service

API TRIM NO: 7

Nominal Trim

410 - Very Hard

Trim code

F6HF+

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6 (13Cr) (250 HBN min)

Seat surface

F6 (13Cr) (750 HB)

Trim Material Grade

13Cr-0.5Ni-1Mo/13Cr-0.5Ni-Mo

Service

Seats 750 BHN min. As trim 1 but for higher pressure and more corrosive/erosive service

API TRIM NO: 8

Nominal Trim

410 - Hard faced

Trim code

F6HFS

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

410 (13Cr) (250 HBN min)

Seat surface

410+St Gr6 (CoCr Alloy) (350 HBN min)

Trim Material Grade

13Cr-0.75Ni-1Mn/1/2Co-Cr-A

Service

Universal trim for general service requiring long service life up to 593°C. As trim 5 for moderate pressure and more corrosive service. Steam, gas and general service to 540°C. Standard trim for gate valves

API TRIM NO: 8A

Nominal Trim

410 - Hard faced

Trim code

F6HFS

Stem and other trim parts

410 (13Cr) (200-275 HBN)

Disc/wedge

F6 (13Cr) (250 HBN min)

Seat surface

410+Hardf. NiCr Alloy (350 HBN min)

Trim Material Grade

13Cr-0.75Ni-1Mn/1/2Co-Cr-A

Service

As trim 5A for moderate pressure and more corrosive service

API TRIM NO: 9

Nominal Trim

Monel®

Trim code

Monel®

Stem and other trim parts

Monel® (NiCu Alloy)

Disc/wedge

Monel 400® (NiCu Alloy)

Seat surface

Monel 400® (NiCu Alloy)

Trim Material Grade

70Ni-30Cu

Service

For corrosive service to 450°C such as acids, alkalies, salt solutions, etc. Very corrosive fluids.

Erosive-corrosive service between -240°C and 480°C. Resistant to sea water, acids, alkalies. Has excellent corrosion resistance in chlorine and alkylation service

API TRIM NO: 10

Nominal Trim

316

Trim code

316

Stem and other trim parts

316 (18Cr-Ni-Mo)

Disc/wedge

316 (18Cr-Ni-Mo)

Seat surface

316 (18Cr-Ni-Mo)

Trim Material Grade

18Cr-12Ni-2.5Mo-2Mn

Service

For superior resistance to corrosion for liquids and gases which are corrosive to 410 stainless steel up to 455°C. As trim 2 but a higher level of corrosive service. Provides excellent resistance to corrosive media at high temperatures and toughness for service at low temperatures. Low temperature service standard for 316SS valves

API TRIM NO: 11

Nominal Trim

Monel - Hard faced

Trim code

MonelHFS

Stem and other trim parts

Monel® (NiCu Alloy)

Disc/wedge

Monel® (NiCu Alloy)

Seat surface

Monel 400®+St Gr6 (350 HBN min)

Trim Material Grade

70Ni-30Cu/1/2Co-Cr-A

Service

As trim 9 but for medium pressure and more corrosive service

API TRIM NO: 11A

Nominal Trim

Monel - Hard faced

Trim code

MonelHFS

Stem and other trim parts

Monel® (NiCu Alloy)

Disc/wedge

Monel® (NiCu Alloy)

Seat surface

Monel 400T+HF NiCr Alloy (350 HBN min)

Trim Material Grade

70Ni-30Cu/1/2Co-Cr-A

Service

As trim 9 but for medium pressure and more corrosive service

API TRIM NO: 12

Nominal Trim

316 - Hard faced

Trim code

316HFS

Stem and other trim parts

316 (Cr-Ni-Mo)

Disc/wedge

316 (18Cr-8Ni-Mo)

Seat surface

316+St Gr6 (350 HBN min)

Trim Material Grade

18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A

Service

As trim 10 but for medium pressure and more corrosive service

API TRIM NO: 12A

Nominal Trim

316 - Hard faced

Trim code

316HFS

Stem and other trim parts

316 (Cr-Ni-Mo)

Disc/wedge

316 (18Cr-8Ni-Mo)

Seat surface

316 Hardf. NiCr Alloy (350 HBN min)

Trim Material Grade

18Cr-12Ni-2.5Mo-2Mn1/2Co-Cr-A

Service

As trim 10 but for medium pressure and more corrosive service

API TRIM NO: 13

Nominal Trim

Alloy 20

Trim code

Alloy 20

Stem and other trim parts

Alloy 20 (19Cr-29Ni)

Disc/wedge

Alloy 20 (19Cr-29Ni)

Seat surface

Alloy 20 (19Cr-29Ni)

Trim Material Grade

29Ni-19Cr-2.5Mo-0.07C

Service

Very corrosive service. For moderate pressure between -45°C and 320°C

API TRIM NO: 14

Nominal Trim

Alloy 20 - Hard faced

Trim code

Alloy 20HFS

Stem and other trim parts

Alloy 20 (19Cr-29Ni)

Disc/wedge

Alloy 20 (19Cr-29Ni)

Seat surface

Alloy 20 St Gr6 (350 HBN min)

Trim Material Grade

29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A

Service

As trim 13 but for medium pressure and more corrosive service

API TRIM NO: 14A

Nominal Trim

Alloy 20 - Hard faced

Trim code

Alloy 20HFS

Stem and other trim parts

Alloy 20 (19Cr-29Ni)

Disc/wedge

Alloy 20 (19Cr-29Ni)

Seat surface

Alloy 20 Hardf. NiCr Alloy (350 HBN min)

Trim Material Grade

29Ni-19Cr-2.5Mo-0.07C/1/2Co-Cr-A

Service

As trim 13 but for medium pressure and more corrosive service

API TRIM NO: 15

Nominal Trim

304 - Full Hard faced

Trim code

304HS

Stem and other trim parts

304 (18Cr-8Ni-Mo)

Disc/wedge

304St Gr6

Seat surface

304+St Gr6 (350 HBN min)

Trim Material Grade

19Cr-9.5Ni-2Mn-0.08C/1/2Co-Cr-A

Service

As trim 2 but more erosive service and higher pressure

API TRIM NO: 16

Nominal Trim

316 - Full Hard faced

Trim code

316HF

Stem and other trim parts

316 HF (18Cr-8Ni-Mo)

Disc/wedge

316+St Gr6 (320 HBN min)

Seat surface

316+St Gr6 (350 HBN min)

Trim Material Grade

18Cr-12Ni-2.5Mo-2Mn/Co-Cr-Mo

Service

As trim 10 but more erosive service and higher pressure

API TRIM NO: 17

Nominal Trim

347 - Full Hard faced

Trim code

347HF

Stem and other trim parts

347 HF (18Cr-10Ni-Cb)

Disc/wedge

347+St Gr6 (350 HBN min)

Seat surface

347+St Gr6 (350 HBN min)

Trim Material Grade

18Cr-10Ni-Cb/Co-Cr-A

Service

As trim 13 but more corrosive service and higher pressure. Combines good corrosion resistance with high temperature resistance up to 800°C

API TRIM NO: 18

Nominal Trim

Alloy 20 - Full Hardfaced

Trim code

Alloy 20 HF

Stem and other trim parts

Alloy 20 (19Cr-29Ni)

Disc/wedge

Alloy 20+St Gr6 (350 HBN min)

Seat surface

Alloy 20+St Gr6 (350 HBN min)

Trim Material Grade

19 Cr-29Ni/Co-Cr-A

Service

As trim 13 but more corrosive service and higher pressure. Water, gas or low pressure steam to 230°C

API TRIM NO: Special

Nominal Trim

Bronze

Trim code

Bronze

Stem and other trim parts

410 (CR13)

Disc/wedge

Bronze

Seat surface

Bronze

Service

Water, oil, gas, or low pressure steam to 232°C

API TRIM NO: Special

Nominal Trim

Alloy 625

Trim code

Alloy 625

Stem and other trim parts

Alloy 625

Disc/wedge

Alloy 625

Seat surface

Alloy 625

API TRIM NO: NACE

Specially treated 316 or 410 trim combined with B7M bolts and 2HM nuts to meet NACE MR-01-75 requirements

API TRIM NO: Full Stellite

Full Hardfaced trim, suitable for abrasive and severe services up to 1200°F (650°C)

Note: Data provided about API Trim numbers is for informational purposes only. Always consult current API publications to verify information and trim date